Modular welding technology with robotic automation

Automated spot welding for industrial series production

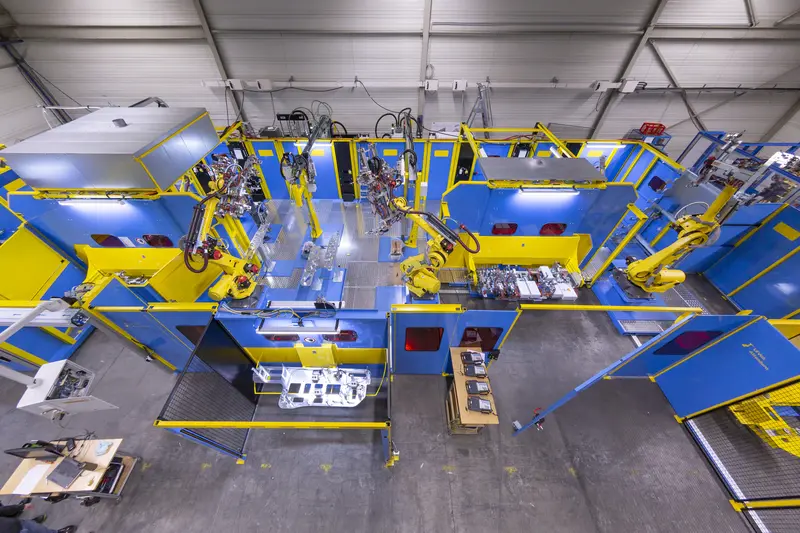

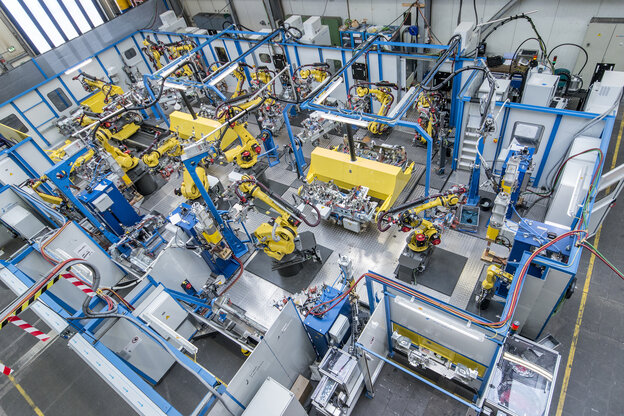

With SpeedLine®, LEWA Attendorn presents a modular production system for automated resistance spot welding in industrial production lines. The system combines robot-compatible components—from spot welding guns to welding cells—into a comprehensive solution for series production.

All SpeedLine® products are integral components of a system architecture. They are not offered as individual devices, but exclusively as modular units within an application-specific system solution. The result: maximum productivity, minimum cycle times, and scalable process reliability in the smallest of spaces.

Spot welding machines for industrial applications

SpeedLine® products for automated spot welding

The SpeedLine® comprises three perfectly coordinated modules for automated resistance spot welding in high-frequency production environments. Each product is an integral part of the overall system – individually configurable, robust, and optimized for performance.

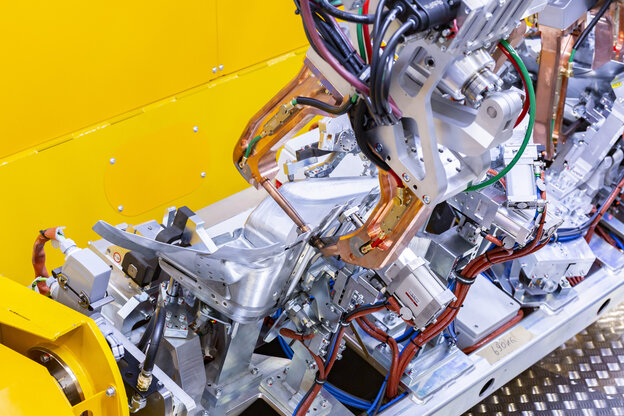

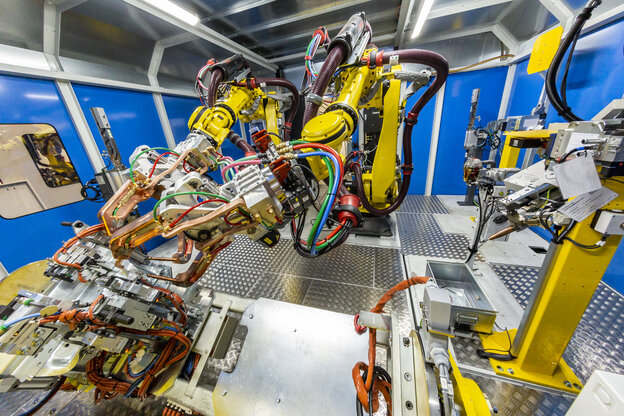

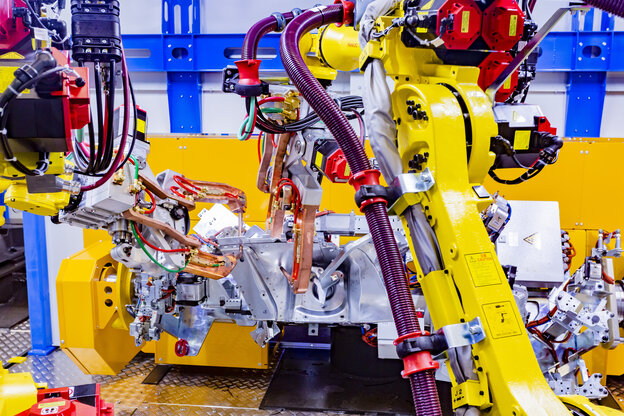

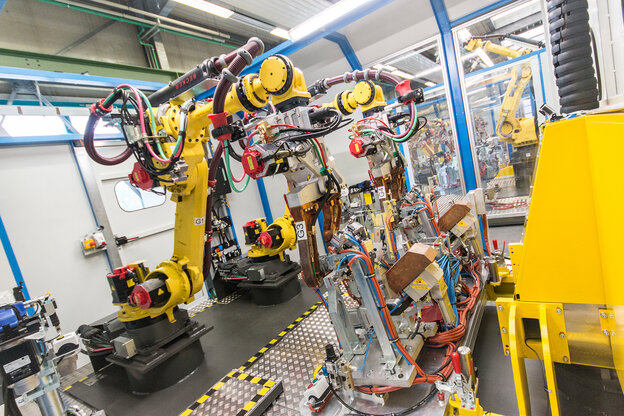

spot welding cell

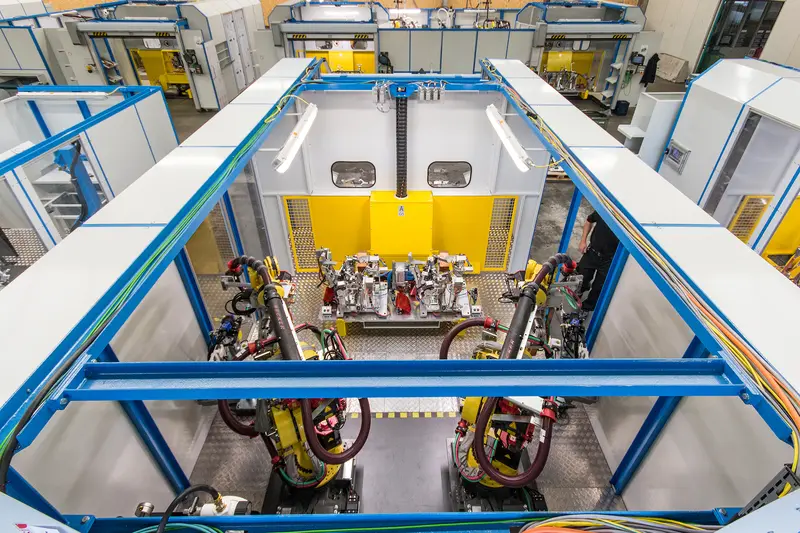

SpeedCell®

The compact spot welding cell: Fully integrated cell with modular design for maximum process speed and minimum cycle times in the smallest of spaces

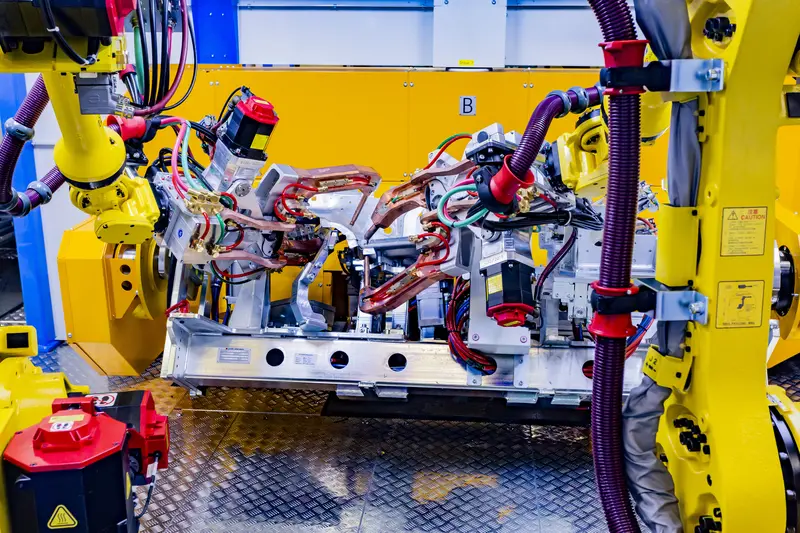

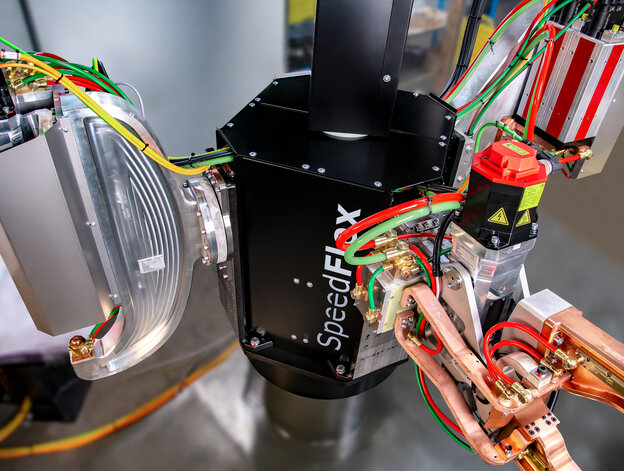

spot welding gun

SpeedGun®

The integrated spot welding gun: Lightweight welding gun with high dynamics for extremely short gun closing times and efficient robot welding with minimal energy consumption

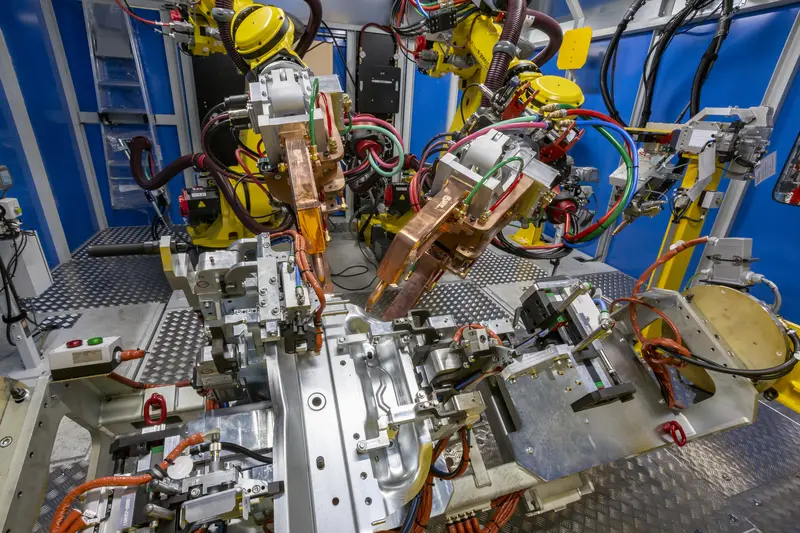

rotary welding table

SpeedFrame®

The automated welding rotary table: Two-station system with high acceleration values for fastest part feeding and reliable component rotation

Highest processspeed

Each SpeedCell® is designed with short signal paths, fast servo drives for maximum cycle times, and optimized component changes for minimal downtime.

Compressed air-free operation

All pliers operate electromechanically without the need for complex compressed air generation. This reduces energy consumption and maintenance costs.

Reliability in continuous operation

Every component is designed for high volumes and long operating times: with high availability even in multi-shift operation.

Seamless system integration

Robots, welding technology, and peripherals work together with a control concept. Integration into existing production lines is ready to connect and time-efficient.

Welding process for the highest demands

Features of our SpeedLine® welding technology

The SpeedLine® was designed for top industrial performance. Its components combine speed, precision, and efficiency: from the control system to the gripper mechanism.

Applications for automated spot welding in industry

SpeedLine® is designed for industrial use in highly automated series production. Whether vehicle bodies, structural components, or sheet metal components—the system impresses wherever speed, repeatability, and process availability are important.

Contact us now

Would you like to find out whether SpeedLine® can make your production faster, more compact, and more efficient? Our application technology and sales engineers will be happy to advise you personally.

Phone: +49 27 22

66-0Email: infolewa-attendorncom

Or use our contact form. We will get back to you as soon as possible.